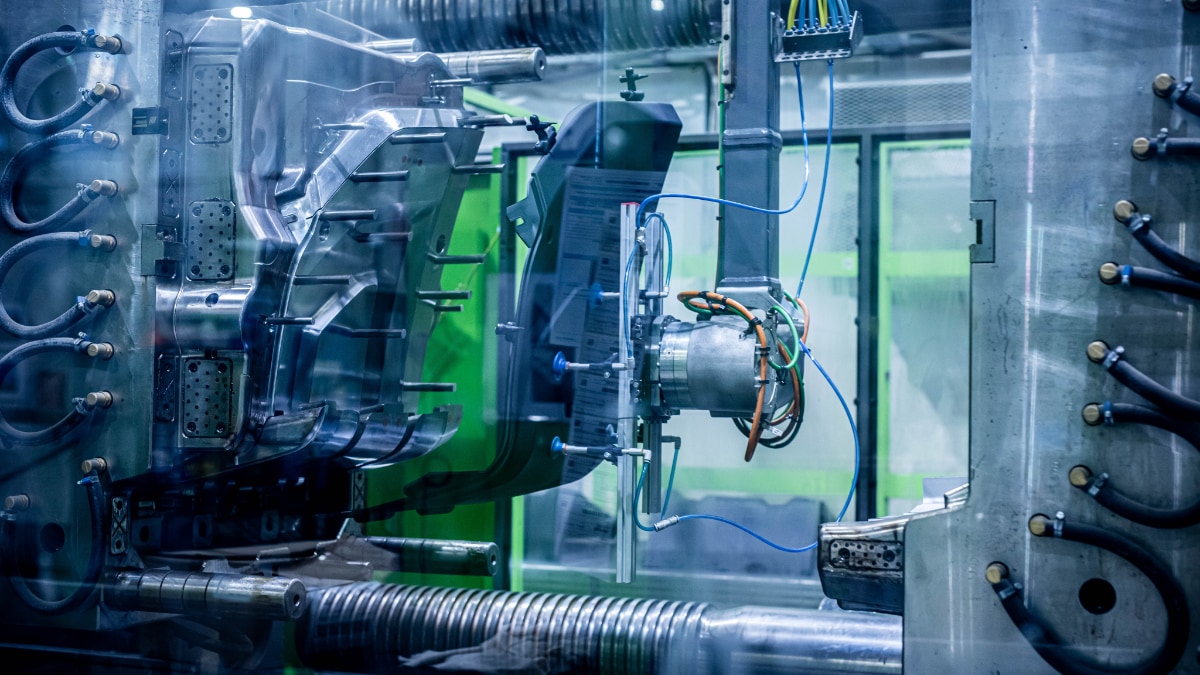

In injection moulding, the melted plastic mass is injected into the mould with high pressure. The injection moulding method enables the high-quality, cost-effective serial production of plastic products with precise measurements. Plastic injection moulding or transfer moulding is a great choice for the production of thousands or pieces, in other words, large batch sizes.

Okartek’s injection moulding process is a precise expert process with controlled automation.

In the first stage, the plastic granulates are melted with pressure, friction and heat as the screw pulls back and pushes the melted plastic mass forward. Possible dyes, fireproofing agents and UV protective agents are also added in this stage.

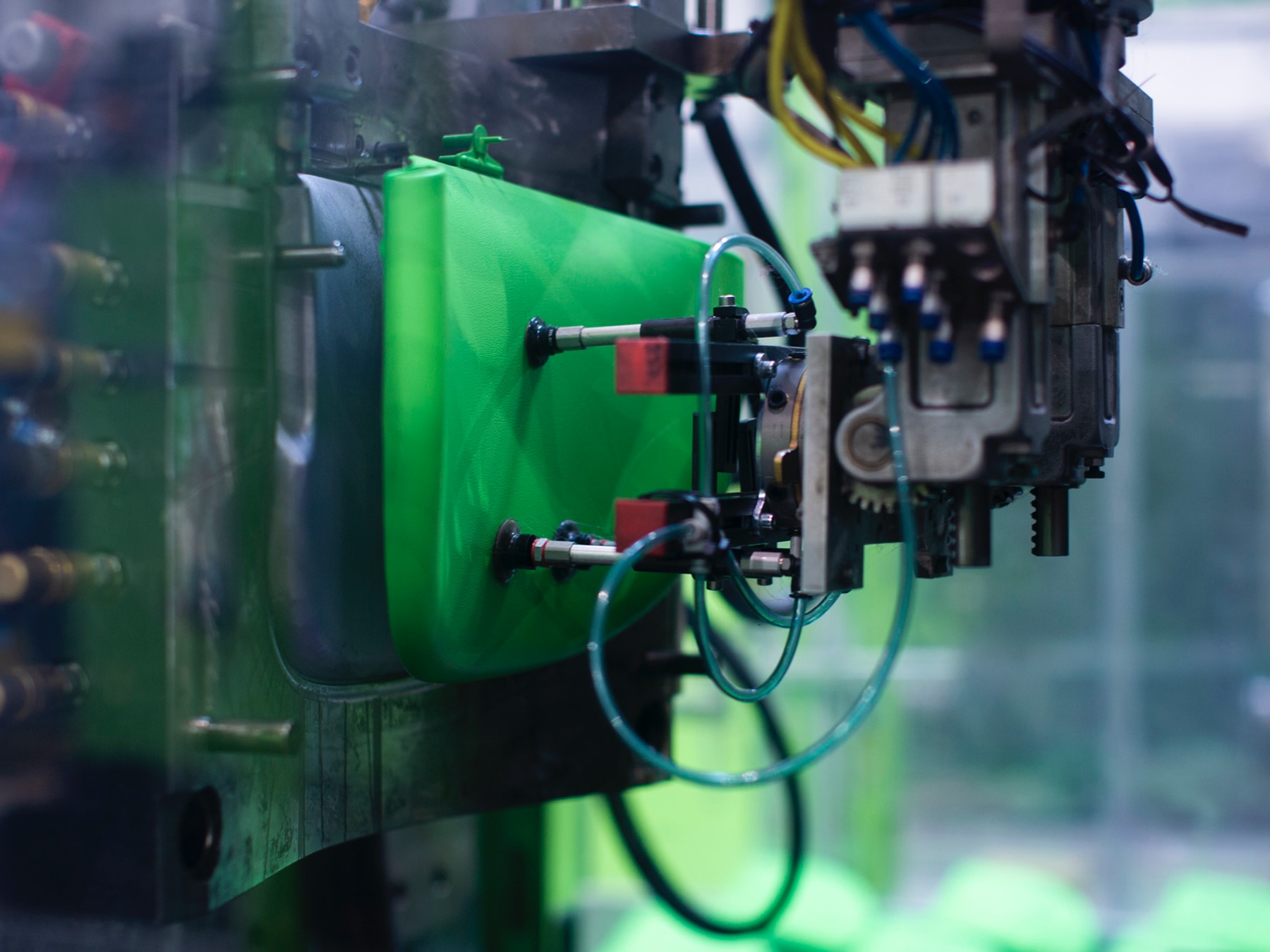

The screw pushes the melted plastic into a steel mould, after which the piece is cooled. The mould is opened and the piece is removed by dropping it or placing it on the belt with the help of a robot.

Okartek provides traditional, gas-assisted and two-component injection moulding. Gas-assisted injection moulding helps make thick-walled products lighter, enabling the manufacture of massive yet light products. The process makes it possible to achieve a honeycomb structure which is both sturdy and light.

In multi-material or two-component injection moulding, multiple materials are moulded into the piece at the same time.

We pay attention to environmentally friendly processes, for example by offering the option of using the biobased ISCC Plus certified material, by reusing any excess pieces created when starting and finishing production as well as reusing the casting conductor as raw material either immediately or later.

Injection moulding enables extremely cost-effective manufacturing of plastic products with precise measurements. The technology also provides a considerably larger variety of options for product design, compared to processes such as plastic thermoforming.

Technical and precise products in injection moulding

We have access to all the known supplier networks. We also guarantee that we will find the plastic material that meets the requirements of every client.

Okartek is a European operator that guarantees a cost-effective injection moulding service and high-quality products. We have received international recognition for our new product project management process and we have wide-ranging experience in various sectors of industry, mould procurement and product materials.

For more information, contact our sales team: sales@okartek.fi