Bio-based plastic

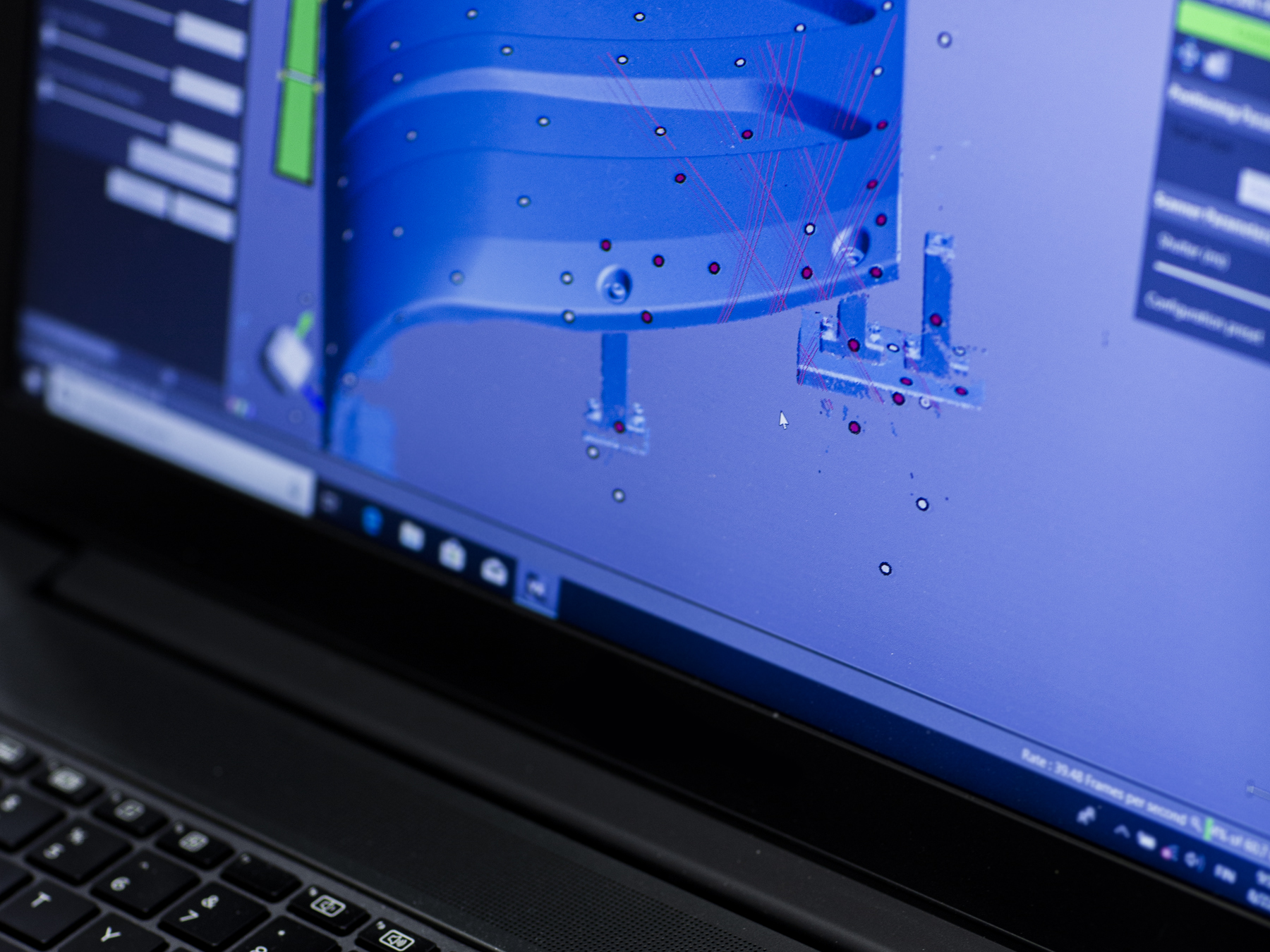

In addition to bio-based and recycled materials, we at Okartek can use certified materials that allow the non-fossil origin of the bio-plastic raw material to be reliably verified.

In addition to bio-based and recycled materials, we at Okartek can use certified materials that allow the non-fossil origin of the bio-plastic raw material to be reliably verified.

Everything starts with solving a very tiny or massive slice of a challenge. To achieve the best possible outcome, a lot of effort is put into research and material choices. The first key to overcoming the challenge is to see things objectively – how does it work in practice.

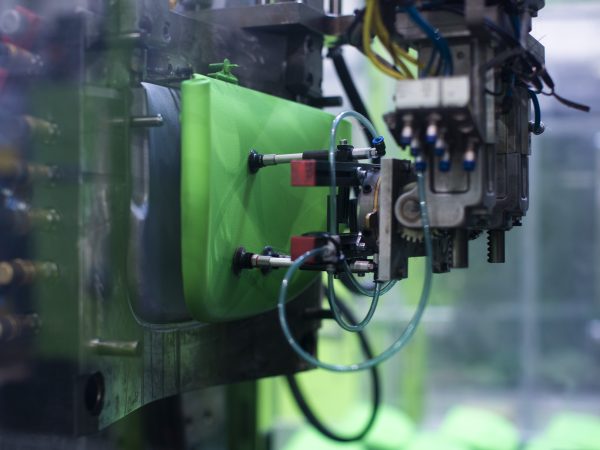

Injection moulding is a manufacturing technique where molten plastic mass is injected under high pressure into the cavity of a metal die. This technique is the most common way to produce large volumes of high quality and dimensionally accurate plastic parts for every kind of industrial use.

Thermoforming is a manufacturing process where thin plastic sheets are heated in order to make them easy to manipulate. This technique is perfect for larger plastic pieces and smaller production quantities. Thermoforming is commonly used to produce parts for agriculture and furniture industries, for instance.

Plastics products often consist of several parts. For this reason, we also offer a comprehensive assembling service that covers chemical composition and bonding, printing, ultrasound welding and if needed, the whole packaging process from the beginning to the finals sales packages.

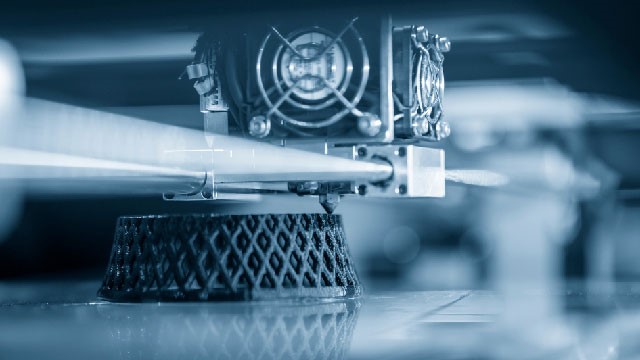

Are you looking for a solution to challenges such as product development and design that require flexible testing, or to speed up the start of production? Okartek offers industrial-grade 3D printing for all needs that require certain mechanical and/or chemical properties.

Our delivery and logistics are recognized and awarded internationally. Each year we deliver thousands of products around the world, and that in mind we’ve put a lot of effort into creating a solid storage and delivery chain. It’s a combination of reliability and efficiency where the network of partners plays a key role.